|

|

Taiwan Component Suppliers Achieve Outstanding Results as

the Demand for E-Scooters in the Global Market Rises

Leading internationally in manufacturing complete vehicles, motors, batteries,

charging stations and electronic control technology

|

|

|

|

The new energy vehicle market will highlight e-scooters in this year. The Industrial Technology Research Institute in Taiwan reported that the number of e-scooters sold worldwide in 2018 reached 998,000, with Asia as the key driver of growth. Asia, Europe, and the Americas accounted for 80.2%, 16.4% and 3.1% of the total respectively. It also forecasts that e-scooter sales will surpass 10% of total scooter sales globally in 2019, and will further expand in the next few years with government policy support worldwide. Compound annual growth rate from 2018 to 2020 will reach 12.1%, with total number sold at 1.355 million and production value exceeding USD 3.3 billion.

Taiwan has long been a producer of scooters, exporting mainly to Asia and Europe. It is also an important import market for scooters internationally. In recent years, Taiwan has been active in developing e-scooters and related parts and components, achieving outstanding results in manufacturing complete vehicles, motors, batteries, charging stations and electronic control technology, and has gradually emerged as a global leader in the e-scooter market.

In addition, Taiwan's e-scooter manufacturers are capable of developing products independently, and have announced plans to introduce electric motorcycles between 2019 and 2020 one after another. They hope to break into the international market, with great potential for further growth as they link up with the world.

|

|

|

PHIHONG TECHNOLOGY CO., LTD. |

|

Hall2,1F, Q0123a Hall2,1F, Q0123a |

|

|

|

With more than 40 years of experience in power conversion technology development, Phihong is one of the world's major power supply manufacturers. It has successfully developed a series of high-performance, energy-efficient charging solutions for electric vehicle recently, including DC charging piles (column type, movable type), AC charging piles (wall-mounted, column-type, portable), as well as various types of DC charging modules, auxiliary power and communication modules, etc., applicable to various types of electric vehicles, including electric buses, private vehicles, e-scooters, logistics vehicles, and various types of special vehicles. Phihong also provides electric vehicle charging software solutions.

|

|

|

|

SINPRO ELECTRONICS CO., LTD. |

|

Hall2,1F, Q0119a Hall2,1F, Q0119a |

|

|

|

Sinpro specializes in power supply manufacturing, committed to applying the latest electric and electronic technologies to power supply and power management systems, and builds customized core power systems for electric vehicles according to unique requests of customers. Its products include power control system for electric vehicles, charging station system, charging device for battery exchange station, DC/DC converter, car charger, and testing equipment. In addition to offering highly-efficient vehicle power systems, Sinpro pays special attention to product reliability. Its products all have traceable production record to ensure quality.

|

|

|

|

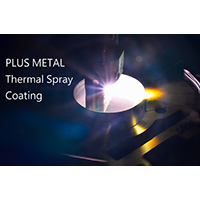

PLUS METAL TECH CO., LTD. |

|

Hall2,1F, Q0216 Hall2,1F, Q0216 |

|

|

|

Plus Metal Tech in Taiwan has expertise in plasma spray welding, thermal spraying and metal surface treatment. Its core technologies include plasma spraying, flame spraying, arc spraying, high velocity oxy-fuel coating spraying (HVOF), as well as cold spraying. Coating materials with specific functions are heated to semi-molten state and sprayed on to the surface of the substrate for various surface modification purposes, an important technical application in the automotive industry. Plus Metal Tech uses sleeve hole spray coating equipment to spray self-lubricating material onto cylinder inner wall. Its porous structure naturally forms an oil film to protect the inner wall of the engine in operation, thereby replacing electroplating process or cylinder liner. In addition, Plus Metal has newly developed cold spraying technology suitable for metals such as copper, aluminum and gold, spraying easily oxidized metal onto moldable substrate to form a dense and non-oxidizing coating.

|

|

|

|