“Optimize the Ecology & Environment, Benefit the Living & Beings” is GSD’svision, GSD believed that “Enterprise is for Public Society”. For many years, GSD focus on Water & Waste water treatment pumps produced & development, besides, the related equipments for waste water treatment application was also introduced as series products, nowadays, GSD already become a company with researching, manufacturing, and technical servicing enterprise.

Brief Introduction of the Products

SMART PUMP

Smart pump(with motor over 37 KW) build-in leakage, temperature, vibration sensors. The pump working data acquisition system. Signal from the jobsite panel or control box can easily send back to GSD cloud platform, to achieved the operation management in digitalize,informationize and visualize. Through GSD cloud platform, the pump’s real-time condition monitoring, alert pre-warning, status diagnosis, trouble shooting situation can send to the operator by mobile phone SMS message, or APP application, so that, all the data, information, analysis, can be collected for equipment/system working management use.

Safety & Reliable: build-in monitoring device, all status been controlled and monitoring by big data checking, predict the shutdown or damage of equipments.

Safety & Reliable: build-in monitoring device, all status been controlled and monitoring by big data checking, predict the shutdown or damage of equipments. Low Cost: reduce the shut-off of equipments, avoid the shutdown of M/C, prolong the motor lifetime, prevent the continuously on-off in working, save the running cost and labor cost.

Low Cost: reduce the shut-off of equipments, avoid the shutdown of M/C, prolong the motor lifetime, prevent the continuously on-off in working, save the running cost and labor cost. High efficiency: running criteria been checked comparing to rated working condition, self adjustment, automatically calibrating to high performance area, energy save and low power comsumption.

High efficiency: running criteria been checked comparing to rated working condition, self adjustment, automatically calibrating to high performance area, energy save and low power comsumption.

PLATE Membrane MBR

Newterra MicroClear MBR reactor, combines special designed patent PP plate with UF features, provides long lifetime and good performance new MBR system.

The MBR reactor submerge in activated sludge tank, the filtrated liquid driven by low pressure difference of the membrane surface, its 0.04um holes of the membrane, can physically stop the particles, bacteria & virus. The effluent with advance water quality, low running cost, goodsystem resistance, few sludge, highly automation also easy for modularity. As a compact unit/system, Newterra MBR can save lots of space, it can be used as the water reuse equipment, or main treatment unit of scaled WWTP.

The Flux up to 30L/㎡h

The Flux up to 30L/㎡h Special membrane design easy for backwashing

Special membrane design easy for backwashing Patent laser welding technique, ensure the plate structure more rigid and durable

Patent laser welding technique, ensure the plate structure more rigid and durable Patent design plate to ensure the filtrated pressure even and well-distributed

Patent design plate to ensure the filtrated pressure even and well-distributed Module design, can stack in different direction as LEGO bricks, the fill up density up to 185㎡/m³

Module design, can stack in different direction as LEGO bricks, the fill up density up to 185㎡/m³ Low energy consumption, easy for maintenance

Low energy consumption, easy for maintenance

The MBR reactor submerge in activated sludge tank, the filtrated liquid driven by low pressure difference of the membrane surface, its 0.04um holes of the membrane, can physically stop the particles, bacteria & virus. The effluent with advance water quality, low running cost, goodsystem resistance, few sludge, highly automation also easy for modularity. As a compact unit/system, Newterra MBR can save lots of space, it can be used as the water reuse equipment, or main treatment unit of scaled WWTP.

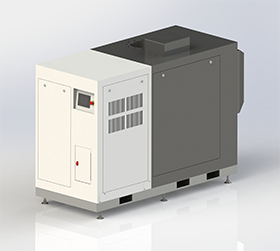

Air Bearing Turbo Blower

Air bearing turbo blower is a totally new concept centrifugal blower, with high efficiency, low noise, low vibration, low wearing features, no additional cooling system, without lubricant system, make it as environmental friendly equipment. The introduced of “high speed motor”&”air bearing” core techniques, get rid of the traditional blower’s bearing, coupling, cooling, lubricant system, achieved its tremendous performance, whole efficiency, energy-saving and running reliability. The M/C need smaller space, easy to installed, exhaust with no oil air, is real oil-free centrifugal blower.

The air bearing blower can running in full design loading, with no vibration, no surge, no leakage, operation within the design curve area’s any point with no overloading situation. All the rotating component passed the static and dynamic calibrated, with no resonance under normal on-load operation. All the parts with stress and strain design tolerance for treatment, delivery, installation and operation.

High efficiency, energy-saving, intelligence

High efficiency, energy-saving, intelligence Low noise, space-saving, easy to installed

Low noise, space-saving, easy to installed 100% oil-free system

100% oil-free system

The air bearing blower can running in full design loading, with no vibration, no surge, no leakage, operation within the design curve area’s any point with no overloading situation. All the rotating component passed the static and dynamic calibrated, with no resonance under normal on-load operation. All the parts with stress and strain design tolerance for treatment, delivery, installation and operation.