About the Company

Combining dehydration, heat pump technologies and air pollution treatment technologies, we integrate techniques and resources into our application products, such as sludge drying system, liquid condensation and crystallization system and VOCs treatment, etc., and diverse peripheral facilities. With a strong technical background, Dilemma provides high quality products and services.

Brief Introduction of the Products

-

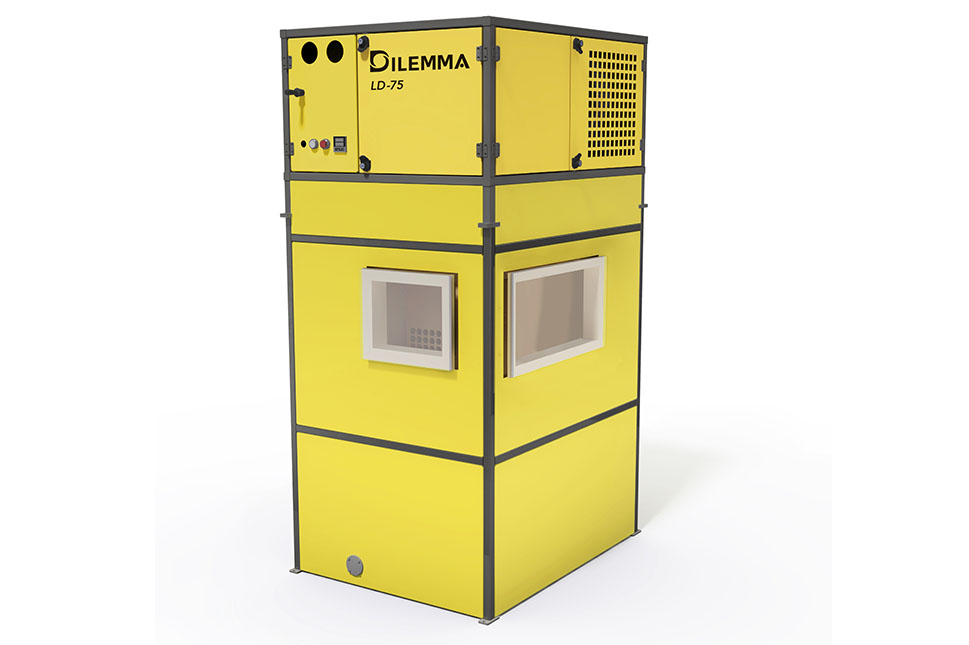

Heat Pump Sludge Drying SystemIn ordinary wastewater treatment, Sludge Cake is directly removed during the dehydration process; however at this stage the sludge still contains about 80% water, a great deal of money is spent for removing the water. With an additional sludge drying system, the weight of sludge can be further reduced by 40-60%; which will significantly reduce the clearing costs. The dried sludge also has merits of lesser footprint and milder odor.

DILEMMA Heat Pump Sludge Dryer reduces sludge weight via Heat Pump Condensation; it costs only $900-1500 of power for removing every ton of water, quite reasonable when compared to ordinary sludge clearing cost that easily exceeds $10,000 per ton; a fast return can be expected

The system also features easy maintenance, no need for tail gas treatment, small floor area, etc. Features

Features- Optimum models for either batch process or continuous process whether of small or large scale treatment.

- Choices of diverse peripheral facilities including feeder, conveyor, holding tank, etc., for combining into turnkey solutions that offer trouble-free procurement.

- Comprehensive service procedures offering pre-purchase test services as well as test runs, maintenance and warrant services that guarantee the most reliable equipment utilization.

-

Liquid Condensation and Crystallization System (Chemical Recycling Machine)Etching liquid for ordinary plating process is discharged periodically at set volumes; however, the effluent contains large amounts of precious metals, it is regrettable if they are directly disposed of in the sludge that is being cleared out. The use of this system not only effectively reduces volume of the waste-liquid to approximately 1/20 but also allows adding a crystallization system based on the demand to further retrieve valuables; the processed etching liquid can even be re-used directly in the production line to achieve benefits of a recycled economy.

This system also applies non-oil condensed liquids without the need of a vacuum tower. The system results in low wear and tear and low power consumption; it also benefits low consumables, low floor area, easy operations and simple maintenance. A wide range of treatment capacities is available for different needs. Features

Features- Environmental engineering for anti-erosion technologies allows semi-customization for optimum equipment with the most suitable materials to handle different types of liquids based on their properties.

- In-house developed crystallization technology allows adjustable condensation based on liquid properties and different requirements. It also allows achieving different levels of crystallization, for retrieving valuable materials from the agent or effective reduction of effluent volume.

- 3. Comprehensive service procedures offering pre-purchase test services as well as test runs, maintenance and warrant services that guarantee the most reliable equipment utilization.

-

Waste Gas Treatment System for Volatile Organic Compounds (VOCs)Combining environmental engineering and air pollution treatment technologies, DILEMMA launched the Low-Temperature VOC Purification System. Compared to pollutant reduction by incineration, this unique system uses multi-layer purification where effective purification catalysts and low-temperature plasma technologies are utilized, thereby making it suitable for decomposing gases containing multiple compounds; the highly effective result ensures safe and reliable use.

In view of the extreme necessity for periodical maintenance of air-pollutant treatment facilities, we offer rental solutions which not only exempt your needs for purchasing the plant but also eliminate your troubles for the subsequent maintenance tasks.

DILEMMA also provides turn-key plant planning; professional design engineers will provide assessments for you, considering versatile mass equivalent technologies with effective savings on the plant volume as well as its costs. Features

Features- Easy operations, simple maintenance and long service life of the equipment.

- Provide turn-key planning of the plant, including engineering of waste gas treatment and relevant systems

- Comprehensive service procedures offering pre-purchase test services as well as test runs, maintenance and warrant services that guarantee the most reliable equipment utilization.