Show News

- Home

- Show News

Under the drive of lightweight and environmental awa reness, the enterprises need to take into account the impact on the environment while produc i ng, and are committed to sustainable development. Among them, the MuCell technology is applied to the manufacture of shoe midsole, replacing chemical foaming with physical foaming. The disadvantages of the traditional manufacturing process, such as long molding time, the generation of a large amount of greenhouse gases, and the non-recyclability of materials, are solved together to achieve sustainable manufacturing.

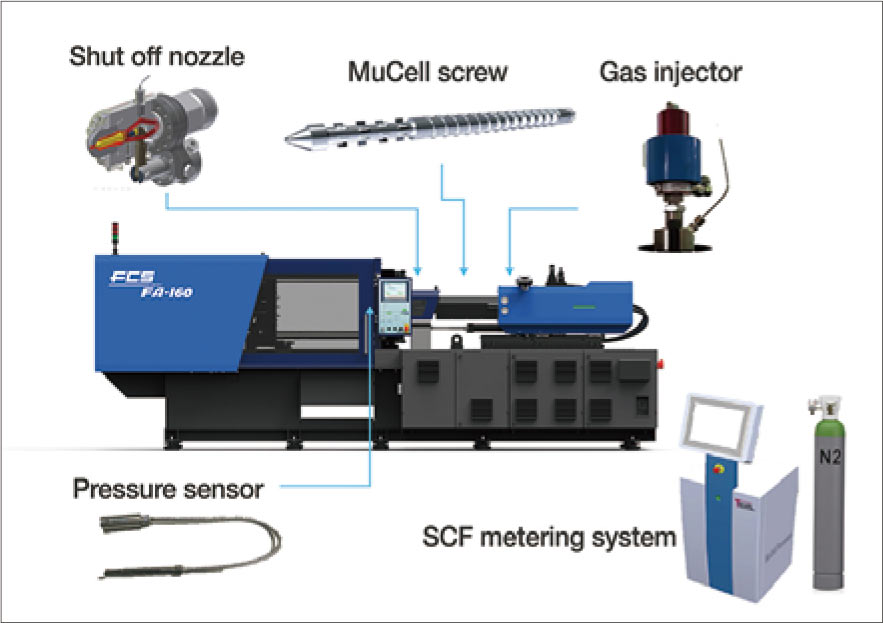

FCS has introduced this technique since 2015, MuCell system uses a special process in screw. This year, FCS has assisted a customer in applying MuCell technology to the midsole process of sports shoes. Most of today's shoe midsoles use the chemical foaming process of EVA material - EVA and foaming agent are mixed to make shoe embryos, and then enter the second process, so that the material undergoes bridging reaction to improve strength, and the product is obtained after cooling. Moreover, the foamed plastic changes from the thermoplastic material to the thermosetting material, which cannot be recycled and is not conducive to sustainable development.

Therefore, FCS and the customer changed the traditional chemical foaming process to the MuCell physical foaming process, adopting nitrogen (N2) as a natural foaming agent. Liquid nitrogen and plastic melt are mixed into a supercritical fluid, accurately measured and injected into the mold cavity. The MuCell physical foaming process is adopted to adjust the density of the foam holes through scientific forming parameters . With different plastic formulations, the midsole can achieve a variety of shock absorption and resiliency.

Duetotheadditionoffoaming agents, activators, and cross-linkers in traditional chemical foaming plastics, the manufacturi n g p rocess emits considerable GHGs, such as carbon dioxide (CO2) and CH4, affecting the atmospheric environment. The MuCell process only uses nitrogen, which greatly reduces the impact on the global environment. In addition to being used in shoe soles, MuCell is also widely used in food packaging, transportation, electrical parts and other fields, effectively helping products achieve dimensional stability, reducing warpage, weight loss, heat preservation, noise reduction and other effects. FCS successfully assists customers indifferent industries to obtain sustainable manufacturing solutions through MuCell technology for injection molding machine.