Show News

- Home

- Show News

The Sustainability Forum was held at TaipeiPLAS on Sept.28, focusing on "zero carbon future" and "sustainable vision" to elaborate the industry's latest developments in smart machinery, advanced materials, and circular solutions.

The world attaches great importance to the environmental protection issues that has been created by climate change. At present, the pulse of technological development in the plastics and rubber industry is deeply affected. Plastics can now be lightweight components for electric vehicles, and composite materials can be used for wind turbine blades required by the green energy industry. In instances of global shipping bottlenecks, re-connecting materials supply with a localized flexible supply chain, and transforming new aviation vehicles and space rockets, are key application areas for sustainable development of the plastics and rubber industry.

The technologies for intelligent manufacturing and green production are maturing. Now, injection and extrusion machinery can achieve multi-layer structure and multi-color production while saving energy, and then use smart monitoring and data collection to achi eve the intelligentization of machinery and equipment, and introduce smart diagnosis for preventive maintenance. These systems can provide machine health evaluation and warnings of abnormalities, and deliver big data on machining status, thus reducing maintenance time and improving accuracy. This will continue to make machinery evolve into more efficient, energy-saving, and low-carbon productivity, and mark the first step into a carbon-zero future.

The new generation of plastic and rubber materials continues to provide core solutions for the sustainable development of various application fields, such as material recycling, sustainable product design, creating a closed cycle path, reducing energy and resource consumption, and reducing carbon/water footprint. Working towards a better future, downstream companies are striving for innovation and cooperation in order to achieve sus tainable development for the industry.

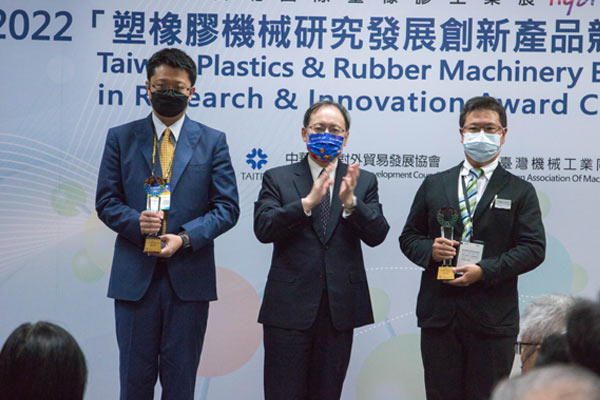

Taiwan Plastics & Rubber Machinery Excellence in Research and Innovation Award symbolizes Taiwan's manufacturing power in advancing plastics and rubber production. This year, a new "Green Machinery Award" has been added, demonstrating Taiwan's machinery role in the newest global plastics trends.

| FIRST PRIZE | FU CHUN SHIN MACHINERY MANUFACTURE CO., LTD. FA160E Advanced Servo Hydraulic IMM with Electric-Driven Injection Unit |

SECOND PRIZE |

HUARONG PLASTIC MACHINERY CO., LTD. HRIB-25 Smart Injection Molding Machinery |

| FIRST PRIZE | EVERPLAST MACHINERY CO., LTD. |

| FIRST PRIZE | CHUMPOWER MACHINERY CORPORATION SS10 Injection Stretch Blow Machine for rPET Application |

SECOND PRIZE |

SUMA PLASTIC MACHINERY CO., LTD. 30iB4 4-Station Injection Blow Molding Machine |

| FIRST PRIZE | TUNG YU HYDRAULIC MACHINERY CO., LTD. |

| FIRST PRIZE | POLYSTAR MACHINERY CO., LTD. |

| FIRST PRIZE | FU CHUN SHIN MACHINERY MANUFACTURE CO., LTD. Servo Pump AI Predictive Monitoring System |

SECOND PRIZE |

TENSO MACHINERY INDUSTRY CO., LTD. HI MORE ROBOT CO., LTD. |

| FIRST PRIZE | HCI CONVERTING EQUIPMENT CO., LTD. FSL-TR Turret Rewind Slitting Machine |

SECOND PRIZE |

WEI CHI MACHINERY CO., LTD. |