Show Topic

AIoT Is Gaining Momentum to Usher in Era of Smart Water

Air suspension bearing centrifugal blower

Concepts such as Industry 4.0 and AIoT have been hot keywords since they were put forward. With the gradual maturity of such technologies as sensors, AI, and 5G networks in recent years, many industries have also begun to formally introduce them into the field applications. Hung-June Hsien, Chairman of the GSD Technologies Co., Ltd., believes: "The water treatment industry has a highly customized feature. Each site has different requirements. The problems faced in different stages of design, construction, installation, adjustment, and operation and maintenance are also different. Even if it is the same sewage source, the composition at different time periods may vary greatly. Therefore, if AI can be used to intelligentize the feedback and control system from a single device to the entire process, the operational efficiency can be optimized and improved greatly through the smart feedback systems.”

The "Smart Water System" of the GSD Technologies Co., Ltd. takes two major aspects of equipment empowerment and program-controlled intelligent connection as the main development strategy. The former is an E-based inspection mechanism to perform smart health inspection and predictive maintenance on the equipment side to improve the proper rate and durability of equipment and to achieve the goal of equipment life extension; the latter is to intelligentize the monitoring and control of each unit in the process, such as sludge sedimentation monitoring, biological activity indicator monitoring, stage inflow control, sludge return control, precise aeration control and other functional control modules. They can respond to changes in water quality, use the AI expert systems and algorithms to make timely adjustments, and accurately adjust and correspond to ensure that the water quality meets the discharge standards, while also saving energy, achieving operational optimization, and reducing operating energy consumption and costs.

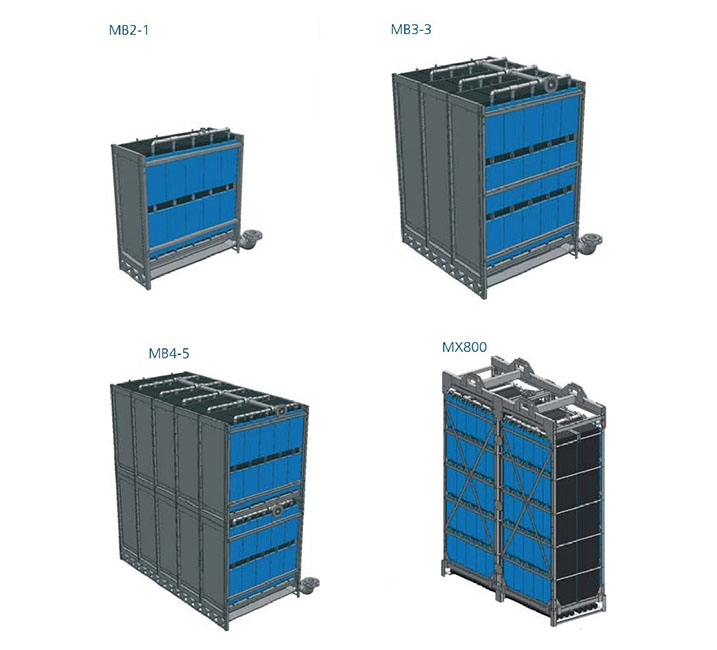

Flat membrane bioreactor

The integration of cross-domain knowledge and high-level talents has always been the core of the GSD Technologies Co., Ltd. Hung-june Hsien pointed out: "Environmental engineers understand the process design but are not familiar with equipment applications. Equipment talents understand model selection and efficiency curves but do not know the overall picture of the system. AI and software talents are good at crossing disciplinary borders but do not know the characteristics of the water industry. It takes to integrate the talents from all these three disciplines and then we can really realize the application of Smart Water (AIoT) and bring benefits."

If big data is used for remodeling, experts are employed to analyze the feedback systems, and adjustments are made through AI deep learning, we shall be able to achieve operational management goals such as improving operational requirements, reducing aeration energy consumption, saving dosing costs, and improving maintenance efficiency. Hung-june Hsien believes: "Water is a problem for all mankind, and smart water is an international trend. Taiwan has leading talents and systems in Asia. I also hope that through this trade show, we can integrate the power of the industries, the governments, the universities, and the research institutes to brainstorm a macro blueprint for future development."