Show Topic

Show Topic

(Image Source: Pixabay)

(Image Source: Pixabay)Wastewater treatment system defines the development of urban civilization. However, the traditional gravity sewer collection system fails to provide a satisfactory solution as human civilization continues to progress. The vacuum sewer system introduced by YE Sail, one of the exhibitors of Taiwan International Water Week (TIWW) 2023 offers "Vacuum sewer systems", a more time-saving, cost-effective and easy-to-maintain alternative to the traditional approach, which can be applied to sewerage and building sewer plans. This ecological solution has been tested globally for more than 50 years and is already mature.

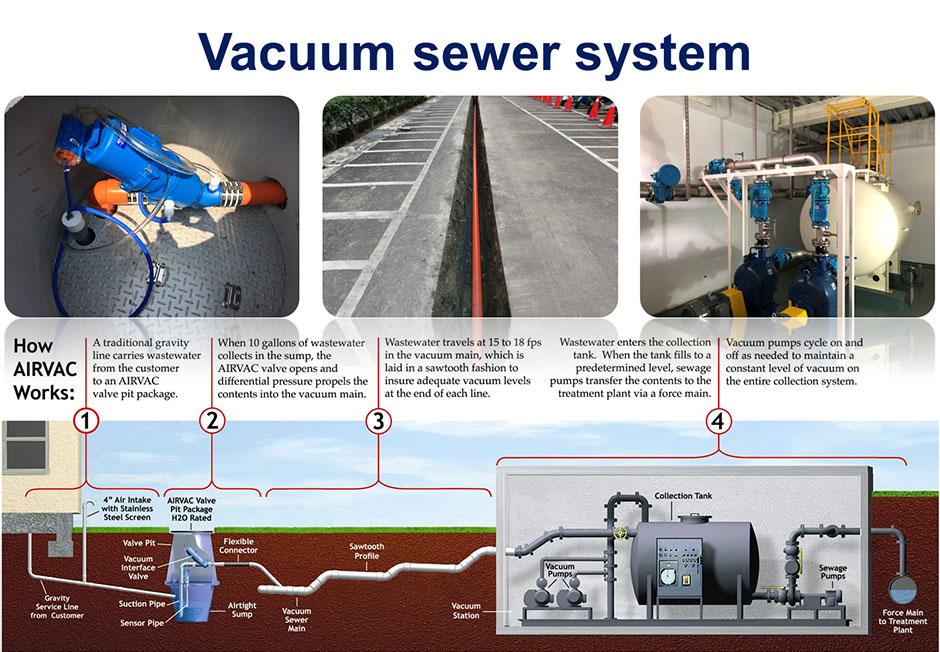

According to Andy Li, business manager of YE Sail, "Simply speaking, gravity lines carry wastewater from customers' homes to the sump portion of the valve pit package. When the wastewater collected reaches a predetermined level, the vacuum valve opens. The differential pressure then propels the wastewater into the vacuum main. Wastewater travels through the vacuum main to the vacuum station. Sewage pumps then transfer the wastewater in the collection tank through a force main to the nearby treatment plant where the water is treated or the public sewer system."

Vacuum Sewer System

Vacuum Sewer SystemThe vacuum main piping from the valve pit to the vacuum station is laid in a sawtooth fashion. Vacuum sewers use smaller diameter pipes and shallower burial depths than conventional gravity sewer systems. The resulting narrow, shallow trenches greatly reduce excavation, dewatering efforts, and surface disruption. In addition, this cost saving technology allows wastewater to flow both horizontally and vertically without hindrance. This flexibility allows for field changes during construction. Obstacles usually can be avoided simply by going under, over, or around them. The ability to make grade changes to satisfy specific needs is certainly an advantage inherent with vacuum sewers.

The horizontal and vertical flexibility allows construction crews to avoid disruption of environmentally sensitive areas. Field changes can easily be made when renovating or repairing old buildings and unforeseen underground obstacles can be avoided. Business manager Li pointed out that, "Dapeng Bay area is close to the shore and has fairly high ground water tables. Conventional sewer system is an expensive solution in such areas. Other special areas such as campus, military camps and jails often requires constructors to finish the project within short time limits to minimize the damage a prolonged overhaul may bring. In the past, constructors must deal with fixed pipes or complex building design when renovating or remolding old building for new purposes. With flexible vacuum piping, these challenges will no longer be a priority."

The new technology also makes maintenance much easier. High flow velocities keep the system free of any blockages, sedimentation or H2S nuisance. Because there is constant vacuum pressure on the completely sealed vacuum sewer collection system, wastewater never leaks into the ground. The system prevents infiltration and inflow of groundwater, protecting the environment from exfiltrating wastewater.

The operation of the valve pit does not require electricity. The only one power source required locates at the vacuum station. A single vacuum station can serve many valve pits in the same area, minimizing construction cost and improving efficiency especially in riverside parks, scenic spots, and amusement parks where buildings or facilities are spread out sporadically within a large area.

Vacuum Sanitary System

Vacuum Sanitary SystemLi mentioned that "If a building is equipped with vacuum toilets, which requires less water for flushing--approximately 1.2 liters per flush, which is about 1/5 of water-saving toilets, this will save up a huge amount of water. For large venues, shopping centers, or commercial buildings where water usage and wastewater treatment is of a prominent issue, the choice shows commitment to water conservation and footprint reduction."

YE Sail has been promoting the vacuum sewer collection technology for more than 10 years, and has already completed more than 6 projects in Taiwan . Besides, YE Sail primarily focused on sewerage infrastructure in the early stage. Now the company will gradually expand their business to building sewer systems, offering customers more water-saving solutions and better conduit designs.