About the Company

GSD Technologies Co., Ltd is a leading company in Environmental equipment whole-sales, development production, also, provides the total solution and technical proposal service to its clients. For many years, GSD was known by most of the customers all over the world through its stable quality & advanced service and got lots of patent also awards.

“Optimize the Ecology & Environment, Benefit the Living & Beings” is GSD’s vision, GSD believed that “Enterprise is for Public Society”. For many years, GSD focus on Water & Waste water treatment pumps produced & development, besides, the related equipment for waste water treatment application was also introduced as series products, nowadays, GSD development smart water、unit intelligent control model、smart machine、PHM(Prognostics and Health Management)、Predictive maintenance and E-inspection, already become a company with researching, manufacturing, and technical servicing enterprise.

“Optimize the Ecology & Environment, Benefit the Living & Beings” is GSD’s vision, GSD believed that “Enterprise is for Public Society”. For many years, GSD focus on Water & Waste water treatment pumps produced & development, besides, the related equipment for waste water treatment application was also introduced as series products, nowadays, GSD development smart water、unit intelligent control model、smart machine、PHM(Prognostics and Health Management)、Predictive maintenance and E-inspection, already become a company with researching, manufacturing, and technical servicing enterprise.

Brief Introduction of the Products

-

GSD Technologies Co.,Ltd. Provide smart machine、Equipment health management、Unit intelligent control module、Predictive maintenance and E-Inspection. Customized equipment supply and technical Services. According to different needs of customers, provide a total solution to our customers.

- Smart Pump、Blower、Mixer、Dehydrator…

- On-line Sludge Settling Detector

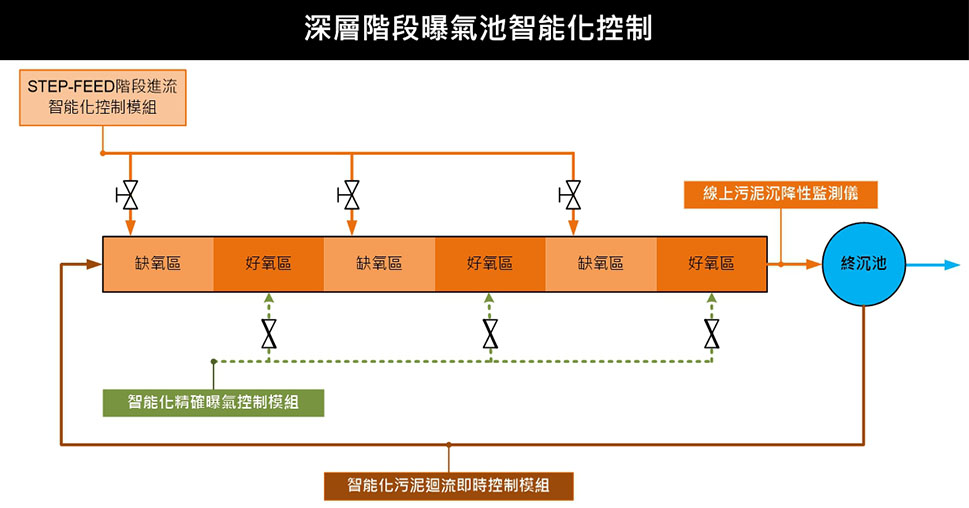

- Smart STEP-FEED Control Module

- Smart Sludge Recycle Control Module

- On-line Bio-Activity Indicator

- Smart Precise Aeration Control Module

- High efficient STEP-FEED aeration tank Control Module

- AIoT Control Module

-

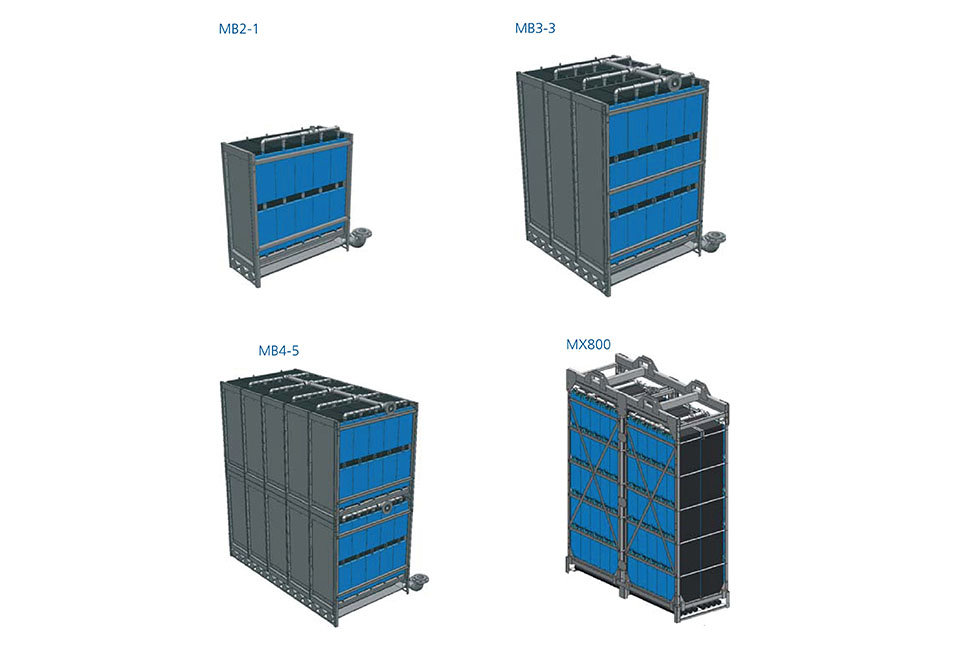

PLATE Membrane MBRNewterra MicroClear MBR reactor, combines special designed patent PP plate with UF features, provides long lifetime and good performance new MBR system.

The MBR reactor submerge in activated sludge tank, the filtrated liquid driven by low pressure difference of the membrane surface, its 0.04um holes of the membrane, can physically stop the particles, bacteria & virus. The effluent with advance water quality, low running cost, good system resistance, few sludge, highly automation also easy for modularity. As a compact unit/system, Newterra MBR can save lots of space, it can be used as the water reuse equipment, or main treatment unit of scaled WWTP. Features

Features- The Flux up to 30L/㎡h

- Special membrane design easy for backwashing

- Patent laser welding technique, ensure the plate structure more rigid and durable

- Patent design plate to ensure the filtrated pressure even and well-distributed

- Module design, can stack in different direction as LEGO bricks, the fill up density up to 185㎡/m³

- Low energy consumption, easy for maintenance

- High efficiency, energy-saving, intelligence

- Low noise, space-saving, easy to installed

- 100% oil-free system

Air bearing turbo blower

Air bearing turbo blower is a totally new concept centrifugal blower, with high efficiency, low noise, low vibration, low wearing features, no additional cooling system, without lubricant system, make it as environmental friendly equipment. The introduced of “high speed motor”&”air bearing” core techniques, get rid of the traditional blower’s bearing, coupling, cooling, lubricant system, achieved its tremendous performance, whole efficiency, energy-saving and running reliability. The M/C need smaller space, easy to installed, exhaust with no oil air, is real oil-free centrifugal blower.

The air bearing blower can running in full design loading, with no vibration, no surge, no leakage, operation within the design curve area’s any point with no overloading situation. All the rotating component passed the static and dynamic calibrated, with no resonance under normal on-load operation. All the parts with stress and strain design tolerance for treatment, delivery, installation and operation.

Features