Exhibitor Info

Exhibitor Info

Water Environment & Other Services Exhibit Area

Water Environment & Other Services Exhibit Area

Quanji is a leading provider of channel system solutions, specializing in high-quality products and equipment for imported sewer testing and channel repair.

With a dedicated staff and a strong technical service team, Quanji brings over 20 years of channel repair experience and close collaboration with international products and technology. This enables the company to offer market-oriented inspection technology and high-quality services, delivering customized solutions to meet customer needs.

Whether it's a single system or a complex network of channels, Quanji provides comprehensive plans for maintenance and updates.

-

Sewer Pipe Rehabilitation Solution

A GFRP liner made of composite material with fiberglass and a specialized resin is utilized. This liner is inserted into the damaged pipeline using the pulling lining method, ensuring a tight fit against the existing pipeline wall. UV heating is applied to solidify the resin, creating a strong and smooth inner lining that restores the pipeline's functionality.

The CIPP (Cure in Place Pipe) technique is employed to minimize disruptions during repairs. The GFRP liner is installed through existing manholes, eliminating the need for extensive construction. After UV curing, the damaged pipeline is renewed with a smooth inner lining, improving sewer water transportation.

-

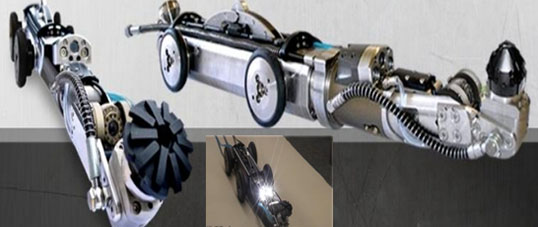

Hydro-cutter 150 And CCTV Inspection Machine for Pipeline Repairing

The HydroCut 150 is a self-propelled robot cutting machine designed for high-power milling and drilling. It efficiently handles various rebar cutting tasks, including waste concrete, epoxy scrap, and tree roots.

Equipped with a fixed CCD camera and high-performance LED lighting, it also serves as a CCTV inspection tool for internal pipeline assessments. This versatile machine combines powerful cutting capabilities with pipeline inspection functionality, making it an effective tool for maintenance and repair.

-

Pressure Pipe Rehab. System

Specializing in high-quality components and solutions for trenchless pressure pipe rehabilitation, this technology caters to pipes up to DN2000 (DN80") and over 232 psi pressure. It is suitable for both waste water recycling and drinking water pipelines.

The trenchless pressure pipe rehab system minimizes environmental impact and reduces costs. It eliminates the need for soil disposal and old pipe removal, resulting in reduced truck traffic. Additionally, it offers shorter construction times and smaller installation pits, ensuring minimal disruptions to traffic.