Exhibitor Info

Exhibitor Info

Water Environment & Other Services Exhibit Area

Water Environment & Other Services Exhibit Area

The "Water Technology Research Division" operates within the Material and Chemical Research Laboratories at Industrial Technology Research Institute (ITRI). With extensive experience in water and wastewater treatment, the division has become a recognized authority in the field. Services are provided to a diverse range of industries, including electronics, flat panel, solar cell, LED, petrochemical, steelmaking, chemical, textile/fiber, food, pulp, and paper.

Comprehensive solutions are offered, tailored to meet the specific requirements of clients. This encompasses feasibility studies, treatability studies, system design, facility installation, and consultation for the management of water treatment systems. The division's expertise and unwavering dedication ensure the delivery of effective and efficient solutions to tackle water-related challenges in various industry sectors.

-

Anammox technology

Anammox (ANoxic AMMonium OXidation) is a cost-effective alternative for removing nitrogen from wastewater. It involves two steps: partial nitrification, where around 50% of ammonium is oxidized to nitrite, and anaerobic ammonium oxidation, where the remaining ammonium and nitrite are converted to nitrogen.

The Anammox process is particularly advantageous for treating wastewater with a low COD/N ratio as it eliminates the need for additional carbon sources, making it more efficient and cost-effective compared to conventional nitrification and denitrification methods.

Features:

Features:- Achieve a 60% reduction in aeration power consumption compared to traditional nitrification reactions.

- Eliminate the need for methanol as a carbon source.

- Reduce waste sludge production by 50% compared to traditional nitrification and denitrification processes.

-

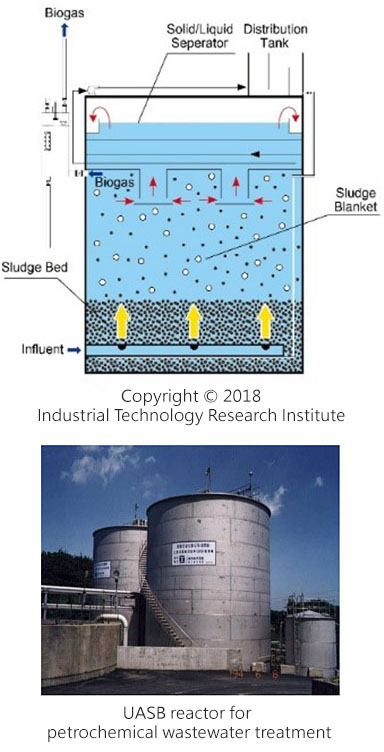

Upflow Anaerobic Sludge Bed (UASB) Process

ITRI's UASB technology is widely used in industrial wastewater treatment for sectors like food processing, distillery, chemical processing, pulp and paper, petrochemical, and optoelectronics.

With over 50 successful cases, the UASB process efficiently treats high-strength organic wastewater. It degrades organic pollutants, generating biogas for energy recovery.

Features:

Features:- Cost-effective investment (reduced land and construction expenses).

- Economical operation (lower power and chemical requirements, reduced sludge yield).

- Potential for energy recovery (methane generation).

-

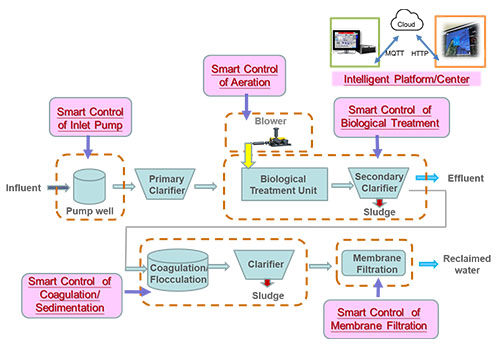

Smart control of water treatment

Intelligent control surpasses automation by adapting to environmental changes. AIoT water treatment combines AIoT, automation, and water treatment expertise to create intelligent solution packages for various water treatment units, including inlet pump, aeration, biological treatment, coagulation/sedimentation, and membrane filtration.

The AIoT system features a visual remote control platform for real-time monitoring and remote operation of water treatment processes.

Features:

Features:- Achieving over 20% savings in operating costs by reducing energy, chemical, and material consumption.

- Enhances system stability, minimizes errors, and provides early warnings.

- Provides comprehensive information for efficient management and decision-making.